-

Signextra:- A printer that’s versatile enough to tackle…

A technology which is capable of effortlessly producing indoor and outdoor durable print upon a huge range of media was never going to confine its talents wholly to satisfying the need for signs. A typical signmaker’s output today confirms this. Signing may represent a company’s core production, but a significant percentage of its work will find its way into applications way beyond signing. It’s a phenomenon that is driving the convergence of what were once defined production disciplines. A signmaker will today do work that once only a screenprinter could do. A photolab may provide its clients with banners. The market is for digital output – many practitioners can, and do, satisfy it.

Seen through the eyes of a suitably equipped company, the convergence of production methods, and the organic expansion of the market for the methods’ output represents a potent commercial opportunity. The market is expanding in application terms too. Digital output today works anywhere traditional printed or fabricated output did, and in thousands of places it never would.

Positioning to exploit this opportunity means having production hardware versatile enough to deal with its demands. Thanks to Roland DG and its VersaCAMM range of printer-cutters, that hardware is within reach, the support needed to operate it is available, and the learning required to flex its muscles is there in depth too.

Roland’s VersaCAMMs are printer-cutters. That’s to say they’re capable of printing images, lettering and logos for example, and then making intricately detailed cuts around and within the printed matter so that it can be removed from the roll material it’s printed on and used in its intended application. Applications for this talent are many and various. Vehicle liveries, general signing, stickers and deckles are all within the scope of a VersaCAMM printer-cutter.

Roland’s VersaCAMMs are versatile in terms of the media or materials they print on to. A huge variety of self-adhesive materials is available, rated according to its intended application. Printable speciality materials exist too, which contribute some effects beyond four colour printing – etch glass effects for windows for example.

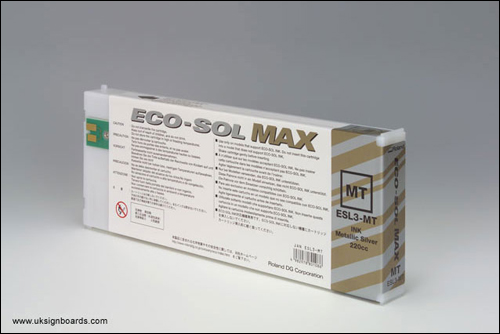

The VersaCAMM range uses Roland’s Eco-Sol Max inks which have a great reputation for the expansive range of colours they can render and the durability of the output they enable. Eco-Sol Max inks don’t just confer great quality and durability on the output they produce, they’re responsible for the reliable operation of the printer too. Routine maintenance requires very little operator involvement with any VersaCAMM printer using Eco-Sol Max inks. The printer takes care of its needs automatically, and very little ink is used in the process. Eco-Sol Max inks also dry quickly, reducing energy consumption and making an already benign ink even better in terms of its environmental impact.

VersaCAMM printer cutters are supplied with Roland’s latest VeraWorks RIP. The RIP takes the users’ designs and turns them into the data the printer needs so that it can execute the job in question. Roland VersaWorks is responsible, in part, for the productivity of the whole system and makes a huge contribution to containing the costs of running it. It optimises ink usage, hence lowering costs of production, and it speeds the end-to-end delivery of the job being produced so lifting productivity beyond what bald performance numbers alone reveal. It even gives ink usage and print time calculations to help maximise efficiencies!

Whatever VersaCAMM printer-cutter you choose, you get a very dependable system capable of sustained performance over the long haul. Advanced media handling and transport systems point to unattended production and greatly reduce cost arising from scrap. A variety of output production modes lets you tackle anything from promotional banners to the finest ‘photo-like rendering on high quality materials. Simple, highly accessible operation makes every production operation as straightforward as the last so you can deal with your competition rather than fight with your printer.

With even modest throughput at competitive market rates, a VersaCAMM printer-cutter makes a very compelling investment, quickly covering its cost and the costs of the consumable materials it uses. A busy VersaCAMM is capable of delivering a big return to the company that uses it and its output will keep customer demand high having established a standard many can only aspire to.

VersaCAMM printer cutters are available in three ranges and a range of sizes suited to the production needs, budget and size the user requires, the most advanced of which is the new VersaCAMM VS-640 – the most powerful VersaCAMM printer-cutter that Roland has ever designed and manufactured. The VS-640 delivers a huge range of marketable benefits to its users. It features a seam-dodging 64” print width, unattended print-cut operation and a next generation print heat for high speed production and stellar quality. Stellar quality though comes at a distinctly down-to-earth price, as does the option to configure the printer with genuine metallic and white inks. The range of new output possibilities, for once, really is confined only by imagination.

To discover more and arrange a personal demonstration on any Roland VersaCAMM printer, visit http://www.rolanddg.co.uk and get real-time updates by following us on Twitter – rolanddguk.

Discover why, with tens of thousands of installations behind it, VersaCAMM is still the printer-cutter with the brightest future.

.

Sorry, there were no replies found.

Log in to reply.