Activity Feed › Forums › Sign Making Discussions › General Sign Topics › Installation of a dimension logo today

-

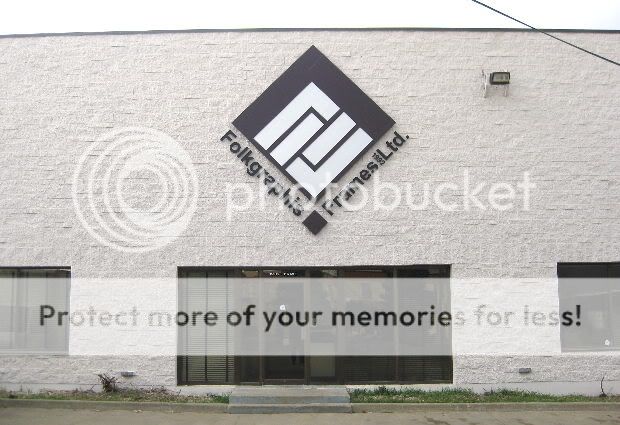

Installation of a dimension logo today

Posted by Duncan Wilkie on May 7, 2009 at 1:08 amIt was a lovely day for working outside. Aaron and I installed this job in the morning.

The logo is cut out MDO mounted on Dibond backer. Plus it is set off the building on a frame. Letters are MDO pinned off…

Duncan Wilkie replied 15 years ago 9 Members · 9 Replies

Duncan Wilkie replied 15 years ago 9 Members · 9 Replies -

9 Replies

-

Great job Duncan, how are those ‘pinned’ letters fitted, set in holes with resin?

You did have a lovely day too by the look of that blue sky.:cool:

Neil

-

very nice,

must have been real fun getting the face of all letters and logo even with such a bumpy surface to mount on… looks more bumpy from afar than close up tho.

a nice contrast too. -

Great looking job Duncan….what did you use to bond to the dibond?

-

Excellent job there Duncan, just needs some subtle window etch work and something on the walls either side of the entrance to give it balance (imho)

Thanks for sharing

Jeremy

-

Looks like you had a better day than me, Duncan!

(I got a root canal)

Turned out swell. Looks really professional.

Sunnier there than here, too, but at least I have Vicodan.

:lol1:

Love….Jilly -

Thanks folks!

The customer wasn’t there when we did the install yesterday, but he just called me to say how happy he is with the job. He’s got a lot of positive feedback already.

Jeremy, that’s a good suggestion, I’ll propose something to him for sure.

Neil, Cheryl, The surface was very rough. Instead of a paper template for installation we make one out of coroplast (corex). Paper gets too distorted over a rough surface like this, and the holes don’t get lined up properly. The coroplast works great, even if you get caught in rain or wind. We mark the holes with a felt pen, remove the template, centre punch the holes and drill. The studs are sealed with silicone.

Harry the dibond is fastened with construction adhesive and screwed to the MDO from behind so no fasteners show.

Jilly, what a rough way to return Stateside after your nice UK tour.

Cheers mates,

Log in to reply.