Activity Feed › Forums › Vinyl Cutter Discussions › Graphtec Vinyl Cutters › Graphtec CE5000 cutting problem, please help?

-

Graphtec CE5000 cutting problem, please help?

Posted by Alexis Davis on February 1, 2009 at 10:45 pmI have been cutting away today no problem, and then all of a sudden the plotter head on my cutter doesn’t drop down to actually cut the vinyl.

Its a CE5000-120 and only about 7-8 months old 🙁

mod-edit

please use descriptive topic titles when posting.

this topic has now been edited.Jayne Marsh replied 15 years, 3 months ago 7 Members · 16 Replies -

16 Replies

-

Alexis , this has never happened to me what software are you using??

Lynn

-

Is the cutter still acting as if its doing the job just with the knife in the raised position?

-

I’m maybe wrong but do you mean the blade holder doesn’t come down far enough for the blade to cut the vinyl or do you mean it doesn’t drop at all?

if its not coming down at all, turn the machine off and look close at the carriage that holds the blade holder. if the section it slides up and down on a clean and try see if anything clogging it. maybe an old tooth brush will help.

once you free it try cleaning above it and all else you can get access to without actually removing anything. then maybe using something like a little artists paint brush apply some wd40 on the plate the holder slides up and down on.

I’m just saying to try that moving part is pretty light and needs to be able to move freely so might just be a build up of dust on the existing lubricant or something like that.as i said, i might be completely wrong but its better to eliminating all silly possibilities before calling out a technician.

-

Alexis,

the first thing to do is scroll through the menu and you should be able to tell the blade to go down and up, if this doesnt work it is a mechanical or electrical problem rather than software,

You can easily remove the cover to the cutting head (a couple of screws I think,) and see if there are any obvious loose conections to the electrics.If the blade does move up and down in the menu, power off the cutter and your computer, and then remove and reconnect the cable,

start up then try again,

if that doesn’t work, try cutting a simple shape from your software, to eliminate a fault in the cut file.Peter

-

sorry about the undescriptive title, I’m in a state of shock I purchased this thinking it would be trouble free knowing someone who has had an old one for 10 years without a hick up.

I am a bit hesitant of removing the cover to see whats under there in case of voiding warranty would that be the case if I removed the cover as it seems to only be them two screws.

Its very odd as I haven’t changed any settings and was just repeating the same set of decals over and over. I’m using signlab v8 btw.

I can see under where the blade drops and the thin metal bar that the head seems to drop up and down on seems to be clear. It has always been very loose and I have been able to move it down but now it is totally rigid and doesn’t want to budge.

-

ok I just thought sod it and took the cover off, I’ve found a screw behind the copper coil that seems to have fallen out from somewhere that is stopping it.

-

edited, Alexis well at least you found the problem, all you need to do now is find where the screw came from.

We have had graftecs for 12 years without problems

hope yours was a one offPeter

-

trying to get the pic out of the manual, so you can see where the screw may have come from.

not the right software on this machine.recommend not used till you can find hole or speak to graphtec in the morn.

as peter says unusualchris

-

Thanks for your help everyone, I would’ve left this until I heard back from my supplier in the morning if it wasn’t for you lot, by then I would’ve severely ticked some people off.

Here’s some pics for future use for anyone, not the best as I dont have my macro lens on 😛

Here is the culprit

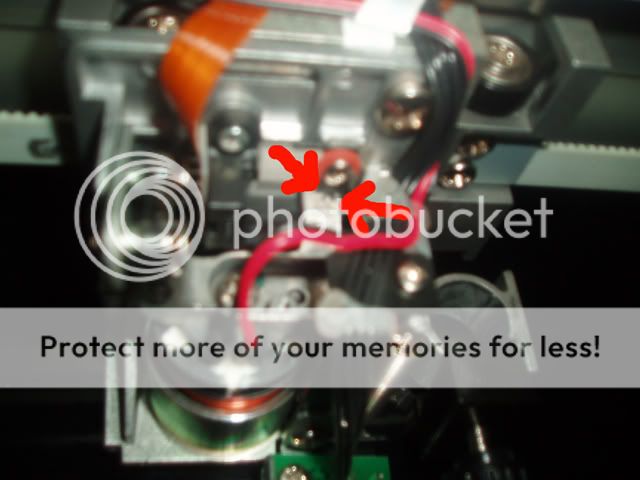

and here is where she fell out, underneath the screw with the red washer

-

quote Chris Wool:trying to get the pic out of the manual, so you can see where the screw may have come from.

not the right software on this machine.recommend not used till you can find hole or speak to graphtec in the morn.

as peter says unusualchris

How do you mean this is not the right software on this machine.

I know of 3 other people running graphtecs with signlab 😕

-

Chris meant he hasnt got the software to get the picture from the the manual, not that signlab is wrong LOL.

Your pics are a bit out of focus, but if you can see where the screw came from, put it back in and see if it works

Peter

-

lol I just that second worked that out after a reread. Yeh my pictures arent the greatest, its only a rubbish little digi cam and doesn’t seem to want to focus. I have managed to get the screw in now and everything seems fine. Thank you all.

-

opps different head assembly mines a fc7000.

that screw looks like the apparent size of one of two used to keep the circuit board on top of the head Assembly.

unfortunately i think you may have to take the top cover off to see.chris

-

I spotted the little red washer hiding down the back too

I could only assume that it went below the other screw with the washer.

please correct me if this is wrong and Ill move it, it just seemed the logical place for it to go. 😕

-

ring graphtec anyway and email the photos

the red washer (plastic one) is normally a insulator not for holding two metal parts together. if you see what i mean

chris

-

I would ring Graphtec service department anyway and check that what you have done is right and wont cause any other problems. If your machine is under warranty you should be able to get help no problem. Anyway phoning them wont cost you any more than a phone call and its better to be safe than sorry. Ive been running my Graphtec for a number of years now and had absolutely no problems 😀

Log in to reply.